PART 2/2

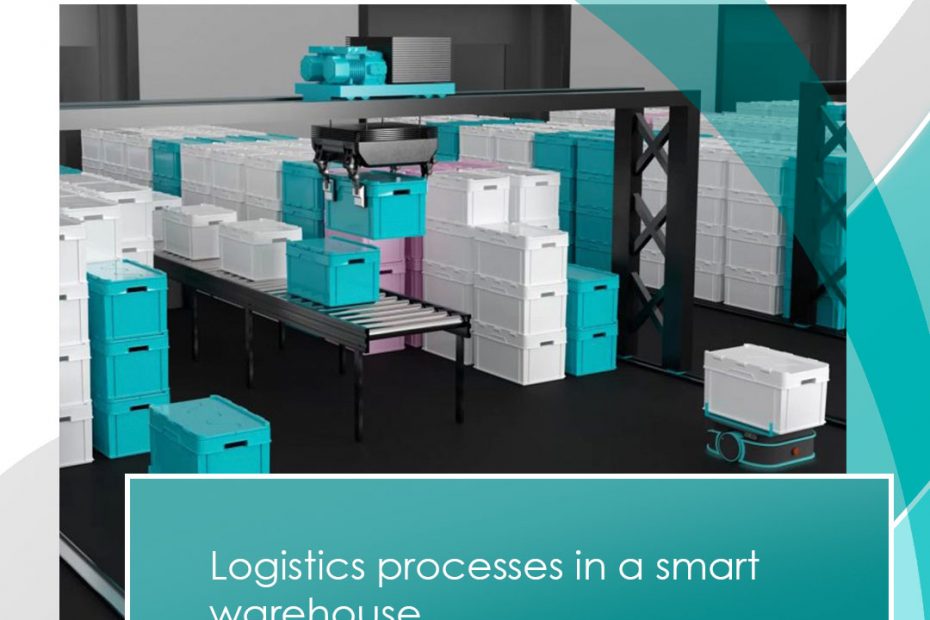

Smart warehouse’s logistics process is a chain of principal logistic operations and actions. It consists of several stages.

stage 1 – Arrival at the warehouse

Path for goods at ICOL smart warehouse begins at their arrival. Goods are loaded onto various types of mobile racks – and are simultaneously distributed by loaders to operative storage areas.

stage 2 – Operational storage and picking

Operational storage areas consist of separate cells, placed above each other in horizontal order. Then picking, combined of 3 steps, happens:

- AGV mobile robot picks a rack with a specific product, then drives it to a picking station.

2. A picking station robot puts a product into a plastic basket.

3. AGV drives the basket to the central high-speed conveyor. From there products come to a sorting area.

stage 3 – Sorting

After central high-speed conveyor goods in baskets come to a sorting station. There robots place goods to transportation packages.

stage 4 – Orders shipping

Goods’ path ends at shipping. Packed goods enter the shipping area, where a robotized crane takes them from AVG carts and positions them close to a shipping dock. As soon as a car/carrier takes the docking position, a special delivery conveyor is activated to help the load.

Smart warehouse provides significant optimization of any warehouse operation. Automation is the trend of today and will be implemented by a growing number of businesses, so don’t leave yourself behind!

To know more: https://smartwarehouse.icol.com/en/smart-warehouse/

Contact us: https://icol.com/en/contacts/